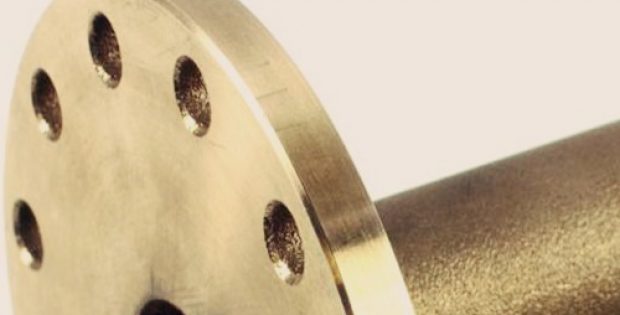

The TRUMPF Group, one of the world’s leading lasers & machine tools manufacturers, has reportedly announced that its new green laser with a pulse product allows printing of copper and other precious metals.

Reports cite, the firm also announced at the Formnext event that its TruPrint 5000 3D printer is capable of printing titanium alloys and high-carbon steel. Reportedly, the German company is looking to expand the versatility of the metal materials for its Additive Manufacturing (AM) technology.

According to a press release by the company, the new green laser also possesses immense potential for gold printing inside the jewelry sector as it allows the production of unique & intricate pieces on demand while also saving costs on expensive materials. Moreover, the TruPrint 5000, which can be pre-heated to about 500° Celsius, can print titanium alloy and high-carbon steel components that don’t warp severely or develop cracks.

The General Manager Additive Manufacturing for technology at TRUMPF, Tobias Baur stated that previously while printing titanium alloy & high-carbon steel items, the laser beam used to melt the component surface which then used to rapidly cool-down to the room temperature. These components were not able to cope with the massive temperature drop and used to get warped or developed cracks. Baur further added that the TruPrint 5000’s ability to be heated to 500° Celsius now overcomes this hurdle as the components now experience a lower drop in temperature.

Reportedly, the printer’s pre-heating feature would also prove to be advantageous for the manufacturing of prosthetics and implants as it can now print titanium components, used in these applications, with an improved quality and reduced stress.

Meanwhile, the green laser’s groundbreaking capacity to print pure copper and other valuable metals could potentially have very important implications in plant and mechanical engineering applications, as copper is ideal for making heat exchangers and conductive inductors.